Crushers and breakers are used to reduce size of mined and quarried material for further processing or to size suitable for the intended end use. The goal of a crusher is to crush the given material in to the material with certain size and shape. Information about

سؤال

سؤال

Mobile crushers are track-mounted rock crushing machines that are easily movable on and between production sites. They are widely used in aggregates production, recycling applications, and in mining operations. Mobile crushers can replace stationary crushing systems, which reduces the need for hauling and thus cuts operational costs. Versatility.

سؤال

سؤال

Metso IC automated control system for crushing and sorting process of stone materials (fi g. 5) is developed on the basis of the SCADA system [16] and provides a simple and safe use of the

سؤال

سؤال 32;This PGN includes: air emission limits. emission monitoring methods. best available techniques to control air emissions. application form template. model permit for mobile crushing and screening

32;This PGN includes: air emission limits. emission monitoring methods. best available techniques to control air emissions. application form template. model permit for mobile crushing and screening

سؤال

سؤال

requires a portable plant with screen, NW100GPC(S), NW100HPC-CC, NW220GPD, NW200HPD, NW330GPS, NW300HPS and NW96200HPS are equipped with an on

سؤال

سؤال : 6MB

: 6MBWhether you need a single crusher, a multi-stage process or a complete plant, we assist you with the right design for the most cost-eff ective crushing process. We are the

سؤال

سؤال 32;Crushing & Screening Plant Design Factors. Crushing Plant Design and Layout ConsiderationsCrushing Circuit “A’’ shows a small simple layout for use in mills up to 100 tons. In order to keep the

32;Crushing & Screening Plant Design Factors. Crushing Plant Design and Layout ConsiderationsCrushing Circuit “A’’ shows a small simple layout for use in mills up to 100 tons. In order to keep the

سؤال

سؤال : 2MB

: 2MBThe high performance of the jaw crushing plants is also a result of the dimensions of the crusher inlet of 1,200 x 800 mm and the extra long design of the articulated crusher

سؤال

سؤال

The process – whaT and when The first considerations are at what point in the process the crusher will be used, the type of material, and the output required. Use the table below as a guide. Primary Gyratory Crusher B G G Primary Jaw Crusher G BPrimary HSI

سؤال

سؤال

Increased crushed ore quality which is good for the ball mill 2.0 Literature Review 2.1 Introduction Crushing plants usually consist of set of machines that are put together to form a process to gradually reduce the size of the processed material until the1.

سؤال

سؤال

7.1. A crushing plant delivered ore to a wet grinding mill for further size reduction. The size of crushed ore (F80) was. 4.0 mm and the S.G. 2.8 t/m 3. The work index of the ore was determined as 12.2 kWh/t. A wet ball mill 1 m & سؤال

سؤال

The roller crushers are used for moist and sticky materials. Generally the machines have to be rigid enough to crush also hard inclusions. As the reduction ratio is only about 5:1 a 2-stage crushing is required in most applications. Fast running type crushers like hammer and impact crushers are the simplest and cheapest solution, whenever the

سؤال

سؤال

Mobile crushers and Screens. We offer a wide range of mobile crushers and screens, both tracked and wheeled, to help you process rock in the toughest conditions. This selection includes jaw crushers, impactors, cone crushers, screens and scalpers for quarrying, construction and rock excavation projects. Powerful, agile and fully mobile

سؤال

سؤال

Typical flowsheet of crushing plant Factors affecting crusher performance Figure 2 shows a number of factors that can affect the performance in ore crushing plant. However, these factors can be illustrated by three categories of influence: ore characteristics, equipment factor and operation factor.

سؤال

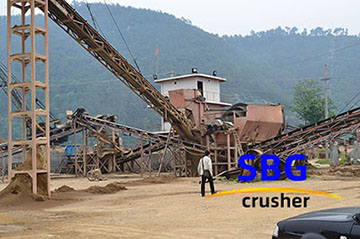

سؤال 32;A crushing plant is a one-stop crushing installation, which can be used for rock crushing, garbage crushing, building materials crushing, and other similar operations. Crushing plants may be either fixed or mobile. Useful aggregates from raw materials like stones, rocks, and minerals as their main function. Draw attention to the

32;A crushing plant is a one-stop crushing installation, which can be used for rock crushing, garbage crushing, building materials crushing, and other similar operations. Crushing plants may be either fixed or mobile. Useful aggregates from raw materials like stones, rocks, and minerals as their main function. Draw attention to the

سؤال

سؤال

Bond's Third Theory of Comminution' calculates the amount of power required to reduce the material by the equation: When adapted to the crushing process, ower becomes a function of reduction ratio and work in iex: Where W = power in kWh per st W, = Bond's crushing work index Pno = size in pm, 80% product passing Fgo = size in pm, 80% feed

سؤال

سؤال

design of a control model utilising two crusher variables and a self-tuning control algorithm. In this research work, a process model describing the dynamic operation of an Osborn 57S gyrasphere cone crusher is investigated. Modelling of the Mowana crushing

سؤال

سؤال

Crusher Lock Out. Install one or more locks to hold the master switch lever in the OFF position. Turn the master key to the OFF position and remove the key. Disconnect the batteries. Place one or more locks on machine control panels, access doors or

سؤال

سؤال 32;CONTENTS Introduction 1.1 Scope of Guidance 1.2 Key Risks 1.3 Typical Layouts 1.4 Feeding 1.5 Blocked Crushers 1.6 Prevention 1.7 Action when a crusher becomes blocked 1.8 Clearing Blockages 1.9

32;CONTENTS Introduction 1.1 Scope of Guidance 1.2 Key Risks 1.3 Typical Layouts 1.4 Feeding 1.5 Blocked Crushers 1.6 Prevention 1.7 Action when a crusher becomes blocked 1.8 Clearing Blockages 1.9

سؤال

سؤال

Mobile thyssenkrupp Polysius crushing plants are in operation all around the world. It was thyssenkrupp that pioneered mobile crushing plants, thereby making it possible to crush minerals directly at the site of extraction and synchronize to the rate of mining advance, into sizes ready for conveyor transport of the crushed material from the mining face to the

سؤال

سؤال 32;Unit processes of crushing, grinding, solidliquid separation, flotation are therefore described in some detail so that a student at graduate level and operators at plants will find this book useful.

32;Unit processes of crushing, grinding, solidliquid separation, flotation are therefore described in some detail so that a student at graduate level and operators at plants will find this book useful.

سؤال

سؤال

MAQCHK-007-Mobile-Crushing-Plant-Inspection-Checklist-V1.4. It is recommended this inspection be completed monthly. Complete the checklist below by ticking / marking the applicable score (Y, N, N/A) for each item. Complete details of non-conformances identified in the space provided. Assign a risk score for each non-conformance using the matrix

سؤال

سؤال 32;Designing a layout. A stone crusher plant designer follows three steps to create the layout: • Process design. • Equipment selection. • Layout. The principal design parameters driving the

32;Designing a layout. A stone crusher plant designer follows three steps to create the layout: • Process design. • Equipment selection. • Layout. The principal design parameters driving the

سؤال

سؤال

maximum reliability. low servicing requirements. high wear resistance. thyssenkrupp builds mobile crushing plants equipped with travelling gears for capacity of 500 to 5,000

سؤال

سؤال

The key elements are process design, equipment selection and layout. Crusher availabilities need to take into account crusher liner and screen cloth replacement (Connelly, 2008). The flow sheet specifies the nominal design and the peak production rate. The process design criteria can be calculated from a spread sheet.

سؤال

سؤال 32;Six crusher plant sites were selected based on their varying production capacity for the study. Accordingly, selected sites were visited to carry out area noise and whole-body vibration surveys.

32;Six crusher plant sites were selected based on their varying production capacity for the study. Accordingly, selected sites were visited to carry out area noise and whole-body vibration surveys.

سؤال

سؤال

The benefits of our systems are numerous: high throughput coupled with low costs, minimum maintenance, ease of operation and maximum reliability. thyssenkrupp jaw crushers are mainly designed to crush medium-hard to very hard materials. When it comes to the crunch, crushing systems from thyssenkrupp Industrial Solutions offer the ultimate

سؤال

سؤال 32;Dependability and long service life are landmarks of good primary crusher design of up to 30 yrs. The selection of the primary crusher must consider best-in-breed maintenance services as the whole

32;Dependability and long service life are landmarks of good primary crusher design of up to 30 yrs. The selection of the primary crusher must consider best-in-breed maintenance services as the whole

سؤال

سؤال

You cannot select more than 25 topics Topics must start with a letter or number, can include dashes ('-') and can be up to 35 characters long.

سؤال

سؤال

Design and Fabrication of Crusher Machine for Plastic Wastes Proceedings of 35th th IRF International Conference, 06 August, 2017, Bengaluru, India 18 c) Detail Design with Fabrication Drawings Fig -3: CAD Model The design of the project was prepared using a

سؤال

سؤال

آلة تكسير الحصى بقدرة 45-1200 طن/ساعة بسعر مناسب، يرجى الاتصال بنا إذا لزم الأمر.

احصل على عرض أسعار